29. Mar 2023

Recycling of plastic-aluminum composites

The case was written by the Danish Agency for Higher Education and Science as part of their case catalog – find it here

Lack of processes to recycle plastic and aluminum

In 2030, greenhouse gas emissions from Danish waste are expected to be around 1.75 million tons, with the largest emissions coming from waste incineration6. In particular, waste consisting of various composite components, such as packaging and canons from the food industry, end up being sent for incineration. This is because there is a lack of processes to separate the different material components so that the individual components can be reused in new products. In particular, materials that consist of both plastic and aluminum (plastic-aluminum composites) are difficult to separate and recycle. This is one of the biggest challenges to achieving the goal of reducing Danish plastic waste, but new technology can now pave the way for thousands of tons of plastic-aluminum composites to be separated and recycled annually in new products.

New technology tested in cluster project

In 2021, the national cluster for environmental technology, CLEAN, carried out a collaborative project on recycling composite materials (materials consisting of more than one substance) with the Danish Technological Institute and the companies Prounit Frames, Bendixen and Vink Plast. Prounit Frames has developed a new technology that can achieve a clean separation and decomposition of used food and beverage cartons into cardboard fibers, plastic and aluminum, respectively. The separation and degradation is achieved through a combination of mechanical, chemical and thermal treatment. The motivation behind the cluster project was to test and adapt the separation technology for handling plastic and aluminum products other than food and beverage cartons, where the materials are also problematic to recycle.

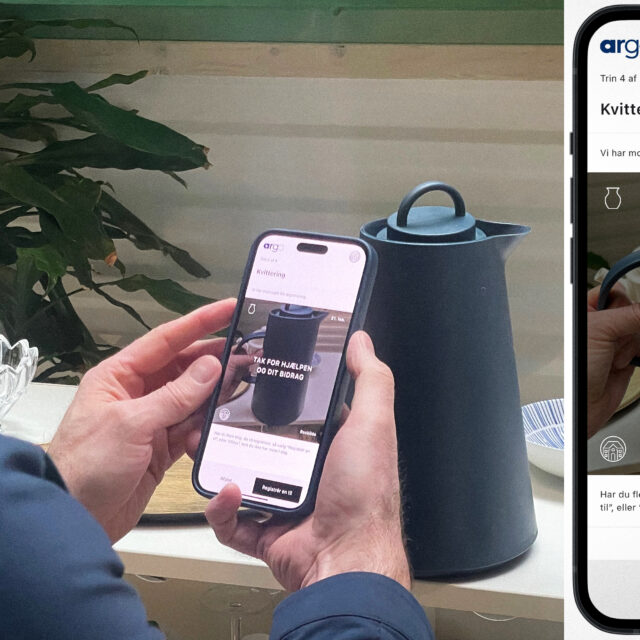

One such product is manufactured by Vink Plast, a company that produces sandwich panels (panels with an aluminum surface and a plastic core), which are often used to produce signs. These sheets are sold to sign manufacturers such as Bendixen, which produces custom-designed signs for customers such as Salling Group and Jysk. Bendixen’s signs are returned after use, making Bendixen responsible for the waste management of the materials. The waste management of the sandwich boards is often complicated, and there is a high demand for being able to recycle more of the materials. The cluster project was driven by the Danish Technological Institute, which engaged relevant companies in the value chain to test whether Prounits Frames’ technology could also be used to separate and recycle the plastic and aluminum in the sandwich panels. The cluster project successfully demonstrated that the plastic-aluminum composites could be separated from the used sandwich panels and that there are economic gains from recycling the materials for the entire value chain.

From pilot study to large-scale collaboration

The cluster project should be seen as a pilot study, where the promising results will be transferred to a larger collaboration to develop and scale up the technology for other product types that also consist of plastic-aluminum composites. This will take place in an even larger circle of partners consisting of actors from other value chains with similar challenges in the recycling of plastic-aluminum composites. The CLEAN cluster will be the driving force behind the continuation of the project and is currently trying to get the project transferred and funded under the Danish Environmental Protection Agency’s development and demonstration program, MUDP. If the project is implemented, it will potentially be possible to recycle thousands of tons of materials annually that would otherwise have been sent to incineration. By recycling the plastic in Vink Plast’s sandwich panels alone, over 1,000 tons of CO2 could be saved annually. If the technology is extended to the rest of the market and subsequently to other types of materials, the CO2 savings can have a significant impact on the green transition.

The Videnbro project ran from November 2021 to May 2022 and was granted DKK 495,000 by the Ministry of Higher Education and Science.

Vil du vide mere?

-

Kasper Gregersen

Communications Consultant

Tel +45 50 78 59 68

kgg@cleancluster.dk

Linkedin